All steam turbines can be classified into two categories; extraction (condensing) steam turbine and non-condensing steam turbine also known as back pressure steam turbines. Both of these steam turbine types have their own operating schemes and benefits which are described here in detail.

Extraction Steam Turbine

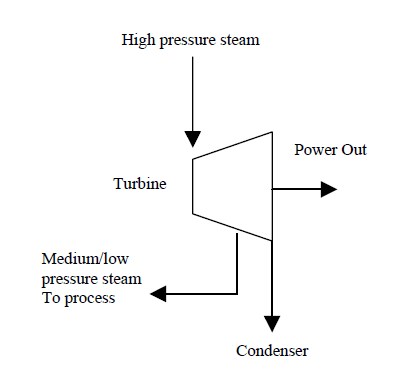

Figure 1: Extraction (condensing) steam turbine

The extraction turbine contains two outlets as shown in figure 1. The first outlet extracts the steam with intermediate pressure for the feeding of the heating process while the second outlet extracts the remaining steam with low-pressure steam for the condensation. The extraction of heat from the first outlet can be stopped to generate more output. Steam control valves at this outlet make this steam very flexible and allow adjusting the output as per demand. The steam from the second outlet goes to the condensation chamber where cooling water brings the temperature of the steam down. The condensed water then goes back to the boiler for the regeneration of the electricity of power, therefore, it is also known as the regenerative steam turbine. The scheme of extraction turbine with cogeneration system is shown in figure 1. This turbine has following benefits and disadvantages.

Advantages:

- This type of steam turbine can be used to generate a high amount of electricity.

- It is a flexible turbine with the ability to regulate output as per changing need.

Disadvantages:

- It is costly turbine with lots of auxiliary components

- Heat rejection in the condensation process reduces the overall efficiency of the system.

- It is usually used on industrial level and requires complex configuration

Figure 1: Extraction (condensing) steam turbine with cogeneration system

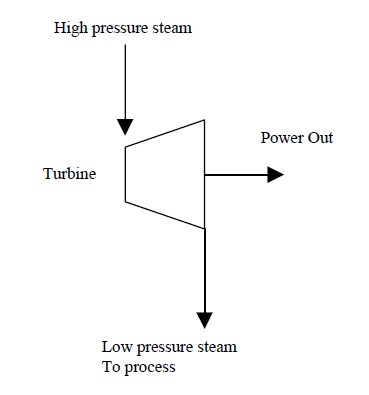

Back Process Steam Turbine

The non-condensing steam turbine uses high-pressure steam for the rotation of blades. This steam then leaves the turbine at the atmospheric pressure or lower pressure. The pressure of outlet steam depends on in the load, therefore, this turbine is also known as the back-pressure steam turbine. This low-pressure steam uses for processing and no steam is used for condensation. The schematic diagram of the back process steam turbine with cogeneration system is shown in figure 2. There are lots of benefits of this steam turbine but at the same time it has few disadvantages which are listed below.

Advantages:

- The configuration of this steam turbine is very simple

- It is relatively inexpensive as compared to extraction steam turbine

- It requires very less or no cooling water

- Its efficiency is higher as it does not reject heat in the condensation process

Disadvantages:

- The biggest disadvantage of this type of steam turbine is that it is highly inflexible. The output of this turbine can’t be regulated as it does not allow changing the pressure and temperature of steam in the turbine, therefore, it works best with the constant load.

- The thermal load of this turbine defines the flow of steam mass which makes it difficult to change the output value. Other methods to regulate output reduce the efficiency of the overall system.

Figure 2: Non-Condensing (Back-Pressure) Steam Turbine