Cross- Flow Turbine is a special type of water turbine designed for mini and micro hydel projects, with low head and high flow.

A German named Fritz Ossberger invented the Cross-Flow Turbine, and hence these type of turbines are often referred as Ossberger turbine in tribute to him.

Principle of Operation

In most water turbines such as the Kaplan and Pelton turbine, the water flows through the turbine axially and leaves the runner in the same manner in the opposite direction.

Here is a YouTube video showing the operation of a Pelton Turbine.

However, the principle of operation is different in the case of Cross-flow turbine. Here, the water enters the turbine transversely and leaves out the turbine after completing two rounds of movement across the runner.

Here is YouTube video showing how the Cross-Flow Turbine works.

In various types of Cross-Flow turbines, there is two associated nozzles for distribution of water. Therefore, that the flow of water movement doesn’t get obstructed.

The movement of water twice across the runner helps to increase the efficiency of the turbine.

Design of a Cross-Flow Turbine

Cross Functional turbine has a higher efficiency than most of the Pelton turbines. Since the Pelton turbine has to fundamentally run at a lower speed than the speed of the incoming jet, it has a lower efficiency of 50%.

Though on paper, we get a higher value of energy for Cross-Flow turbine but till date, only about 61% efficiency has been attained.

To calculate the diameter of the pipe that should be attached, we find that a diameter pipe of 10″ inch is preferred.

The water enters the turbine tangentially and hits the turbine blade. As such, the blade starts moving forward, a motion that results in the rotation of the turbine. At this point, more than 72% of power can be extracted from the water. The remaining 28% can be extracted from the water when the water reaches the inner edge of the turbine.

The leading water jet should make an angle of 16 degrees at the point of contact, and the edge of the blade should be at 30 degrees to the point of contact.

Construction of a Cross-Flow Turbine

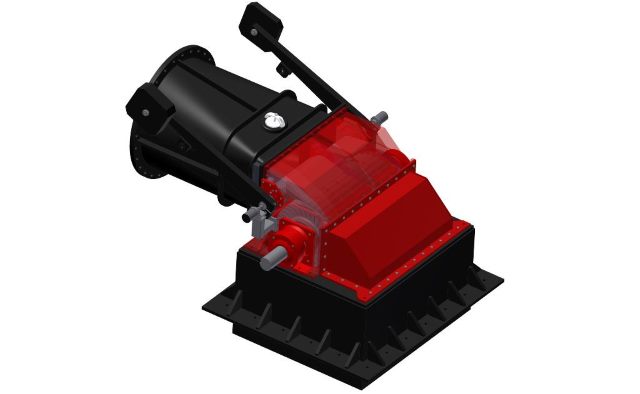

You can have the general outlook of Cross-Flow turbine system in a mini hydro project by referring to the diagram on the page.

(http://www.electway.net/product/cross-flow_turbine.html)

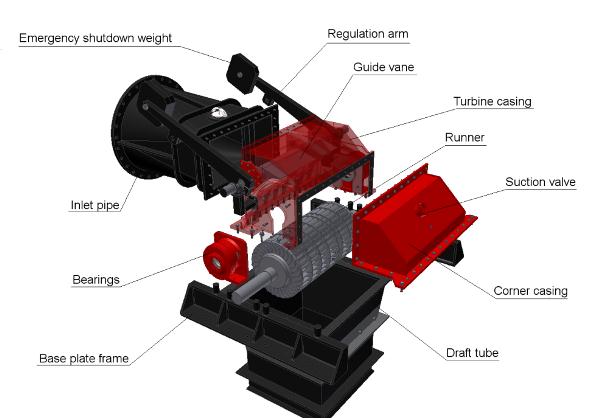

Some of the main parts of a Cross Flow Turbine System:

Guide Vanes- In the OSSBERGER turbine, there are two guide vanes which control the amount of water that is to be passed on to the rotor shaft assembly.

Both of these guide vanes are automatically controlled using advanced servomechanism system. The guide vane bearings are long-lasting and require minimal maintenance.

Casing

The assembly housing is made up of mild steel and protects the assembly from frost and outside damages.

Rotor Shaft Assembly

The Rotors are made up of special steel along with blade assembly placed on the shaft axially. The curved blades are welded to the shaft and produce only limited axial thrust.

Bearings

In most cases, Cross-Flow turbines are fitted with spherical Roller bearings. Roller bearings help in the reduction of frictional force and leakage occurring through the bearing.

Draft tube

These turbines are used in a low-head application, but sometimes depending on the need, they may also be utilized for the medium-head application. In such cases, a draft tube is used for maintaining the water safety and full utilization of the head.

Advantages of Cross Flow Turbine

Cross Flow Turbine technology offers various benefits.

Low-cost Energy solution- It provides an extremely viable energy solution which can be used as a non-distributed source of energy in different remote places.

Low Head Utilisation- Earlier, low-head water source could not be utilized. However, with Cross-flow turbine, we can even use a flat head of 2m.

Higher Efficacy- Cross Flow Turbine operates at higher efficiency than regular Pelton and Kaplan Turbine.

No need of Reservoir- Due to its low-head requirement, it does not often need reservoirs, thus resulting in huge savings and quick implementation.

Application of Cross Flow Turbine

Cross-Flow turbines are used in the various sectors, from low-head micro Hydel plants to off grid stand alone power plant.

Even better, the Cross-Flow technology is re-modified to suit the medium head Hydel project.

Conclusion

So, here is a brief tutorial about Crossflow turbine, its design methodology, advantages and applications showing the great potential for future development. All said and done, it is one aspect of alternative energy we cannot rule out whenever thinking of posterity.