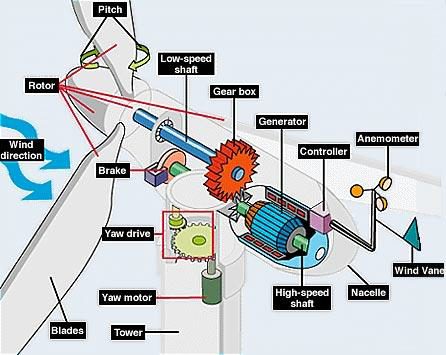

Horizontal-axis wind turbines (HAWT) have the main rotor shaft and electrical generator at the top of a tower, and may be pointed into or out of the wind. Small turbines are pointed by a simple wind vane, while large turbines generally use a wind sensor coupled with a servo motor. Most have a gearbox, which turns the slow rotation of the blades into a quicker rotation that is more suitable to drive an electrical generator.Parts of the wind turbine

Blades

- The lifting style wind turbine blade. These are the most efficiently designed, especially for capturing energy of strong, fast winds. Some European companies actually manufacture a single blade turbine.

- The drag style wind turbine blade, most popularly used for water mills, as seen in the old Dutch windmills. The blades are flattened plates which catch the wind. These are poorly designed for capturing the energy of heightened winds.

The rotor is designed aerodynamically to capture the maximum surface area of wind in order to spin the most ergonomically. The blades are lightweight, durable and corrosion-resistant material. The best materials are composites of fiberglass and reinforced plastic

A gear box magnifies or amplifies the energy output of the rotor. The gear box is situated directly between the rotor and the generator. A rotor rotates the generator (which is protected by a nacelle), as directed by the tailvane.

The generator produces electricity from the rotation of the rotor. Generators come in various sizes, relative to the output you wish to generate. The nacelle is the housing or enclosure that seals and protects the generator and gear box from the elements. It is easily removed for maintenance of the wind

The tailvane directs the turbine to gather maximum wind energy.

Type of wind the HAWT works best in

In general, annual average wind speeds of 5 meters per second (11 mph) are required for gridconnected applications. Annual average wind speeds of 3 to 4 m/s (7-9 mph) may be adequate for non-connected electrical and mechanical applications such as battery charging and water pumping. Wind resources exceeding this speed are available in many parts of the world. A useful way to evaluate the wind resource available at a potential site is the wind power density

Typical lifespan

The lifespan of a modern turbine is pegged at around 120,000 hours or 20-25 years, however, they are not maintenance free. As they contain moving components, some parts will need to be replaced during their working life. Throughout research, the cost of maintenance and parts

replacement is around the 1 cent USD/AU per kWh or 1.5 to 2 percent annually of the original turbine cost.

HAWT Gearboxes

The gearboxes in the traditional horizontal axis wind turbines currently have an average life span of 1.5 years. Replacing these gearboxes can be extremely costly.

Cost Information

Wind turbines for home use vary in price and greatly depend on your electricity needs vs. wind availability, but you can expect to pay around $12,000 to cater for the average home. However, bear in mind that cost can be greatly offset by renewable energy rebates offered by many

governments.

The average price for large, modern wind farms is around 1000 USD per kilowatt electrical power installed. One extra meter of tower will cost you roughly 1500 USD. A special low wind machine with a relatively large rotor diameter will be more expensive than a high wind machine with a small rotor diameter. As you move from a 150 kW machine to a 600 kW machine, prices will roughly triple, rather than quadruple.

The reason is that there are economies of scale up to a certain point, e.g. the amount of manpower involved in building a 150 kW machine is not very different from what is required to build a 600 kW machine. E.g. the safety features, and the amount of electronics required to run a small or a large machine is roughly the same. There may also be (some) economies of scale in operating wind parks rather than individual turbines, although such economies tend to be rather limited

Any Power Output Information

Wind turbines for commercial electricity production usual range from 100 kilowatts to 5 megawatts. At the time of writing, the largest wind turbine in the world had a rotor diameter of 126 m (390 feet) and the potential to generate enough electricity for 5000 households. For a 600 kW turbine, the average output is between 1.5 and 2 GWh per year, depending on wind speed. For every kilowatt hour of electricity produced by wind energy or other green means, approximately 1.5 pounds of carbon is prevented from going into the atmosphere if that electricity had been sourced from coal fired power plants. Carbon dioxide is a major contributor to global warming induced climate change.

Sources 1