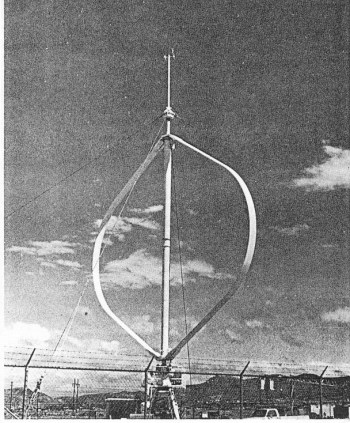

The Darrieus wind turbines was patented in the United States by G. J. M. Darrieus in 1931. It was reinvented by engineers with the National Research Council of Canada in the early 1970’s. Sandia Laboratories built a 5 m diameter Darrieus in 1974, and has been strongly involved with further research on the Darrieus turbine since that time.

Most wind turbines designed for the production of electricity have consisted of a two or three bladed propeller rotating around a horizontal axis. These blades tend to be expensive, high technology items, and the turbine has to be oriented into the wind, another expensive task for the larger machines. These problems have led many researchers in search of simpler and less expensive machines. The variety of such machines seems endless. One that has seen considerable development is the Darrieus wind turbine.

Fig. 1 shows a 17 meter Darrieus built at Sandia. The diameter of the blades is the same as the height, 17 m. The extruded aluminum blades were made by Alcoa (Aluminum Company of America, Alcoa Center, Pennsylvania). This machine is rated at 60 kW in a 12.5 m/s wind.

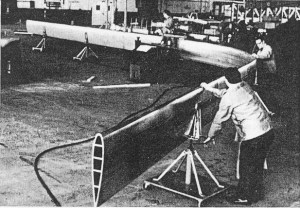

Fig. 2 shows one of the blades during fabrication. Several models of this basic machine were built during 1980.

The Darrieus has several attractive features. One is that the machine rotates about a vertical axis, hence does not need to be turned into the wind. Another is that the blades take the shape of a jumping rope experiencing high centrifugal forces. This shape is called troposkein, from the Greek for turning rope.

Since the blade operates in almost pure tension, a relatively light, inexpensive blade is sufficient. Another advantage is that the power train, generator, and controls are all located near ground level, hence are easier to construct and maintain. The efficiency is nearly as good as that of the horizontal axis propeller turbine, so the Darrieus holds considerable promise as a cost effective turbine.

One disadvantage of the Darrieus is that it is not normally self starting. That is, if the turbine has stopped during a period of low wind speeds, it will not usually start when the wind speed increases. Starting is usually accomplished by an induction motor connected to the local utility network.

This is not necessarily a major disadvantage because the same induction motor can be used as an induction generator to supply power to the utility network when the turbine is at operating speed. Induction machines are simple, rugged, and inexpensive, requiring essentially no controls other than a contactor to connect the machine to the utility network. For these reasons, they are seeing wide use as wind turbine generators.

The first large Darrieus constructed was a 230-kW machine on Magdalen Island, Quebec, Canada in May, 1977 by Dominion Aluminium Fabricators, Limited of Ontario, Canada. The average power output of this machine was 100 kW over the first year of operation, which is quite good. Then a noise was observed in the gearbox so the machine was stopped forinspection and repairs.

During the inspection process, the brakes were removed, which should have been safe because the turbine was not supposed to be able to self start. Unfortunately, on July 6, 1978, the turbine started, and without a load or any way of stopping it, went well over the design speed of 38 r/min. The spoilers did not activate properly,and when the turbine reached 68 r/min a guy wire broke, letting the turbine crash to the ground. Perhaps the main lesson learned from this accident was that the Darrieus will sometimes start under unusual gust conditions and that braking systems need to be designed with this fact in mind.

A major design effort on Darrieus turbines has been made by Alcoa. They first designed a 5.5 m diameter machine which would produce about 8 kW of power, but dropped that size in favor of more economical larger machines. Other sizes developed by Alcoa include a 12.8 m diameter (30 to 60 kW), 17 m diameter (60 to 100 kW), and a 25 m diameter (300 or 500 kW depending on the gear ratio).

The Alcoa effort has been plagued by a number of accidents. A 12.8 m diameter machine collapsed at their Pennsylvania facility on March 21, 1980, when its central torque tube started vibrating and eventually buckled when the machine was running above rated speed.

Then in April, 1981, a 25 m machine crashed in the San Gorgonio Pass east of Los Angeles.The machine itself worked properly to a speed well above rated speed, but a software error in the microcomputer controller prevented proper brake application in high winds. When the machine rotational speed reached 60 r/min, well above the rated speed of 41 r/min, a bolt broke and allowed a blade to flare outward and cut one of the guy wires. The machine then crashed to the ground.

Accidents like these are not uncommon in new technology areas, but they are certainly

frustrating to the people involved. It appears that the various problems are all solvable, but the string of accidents certainly slowed the deployment of Darrieus turbines as compared with the horizontal axis turbines.

Sandia continued work on the theory of the Darrieus turbine during the 1980s, with the result that the turbine is well understood today. It appears that there is no reason the Darrieus could not be an important contributor to the production of power from the wind. It just needs a large aluminum company that is willing and able to do the aluminum extrusions and possibly wait for several years before seeing a significant return on investment.