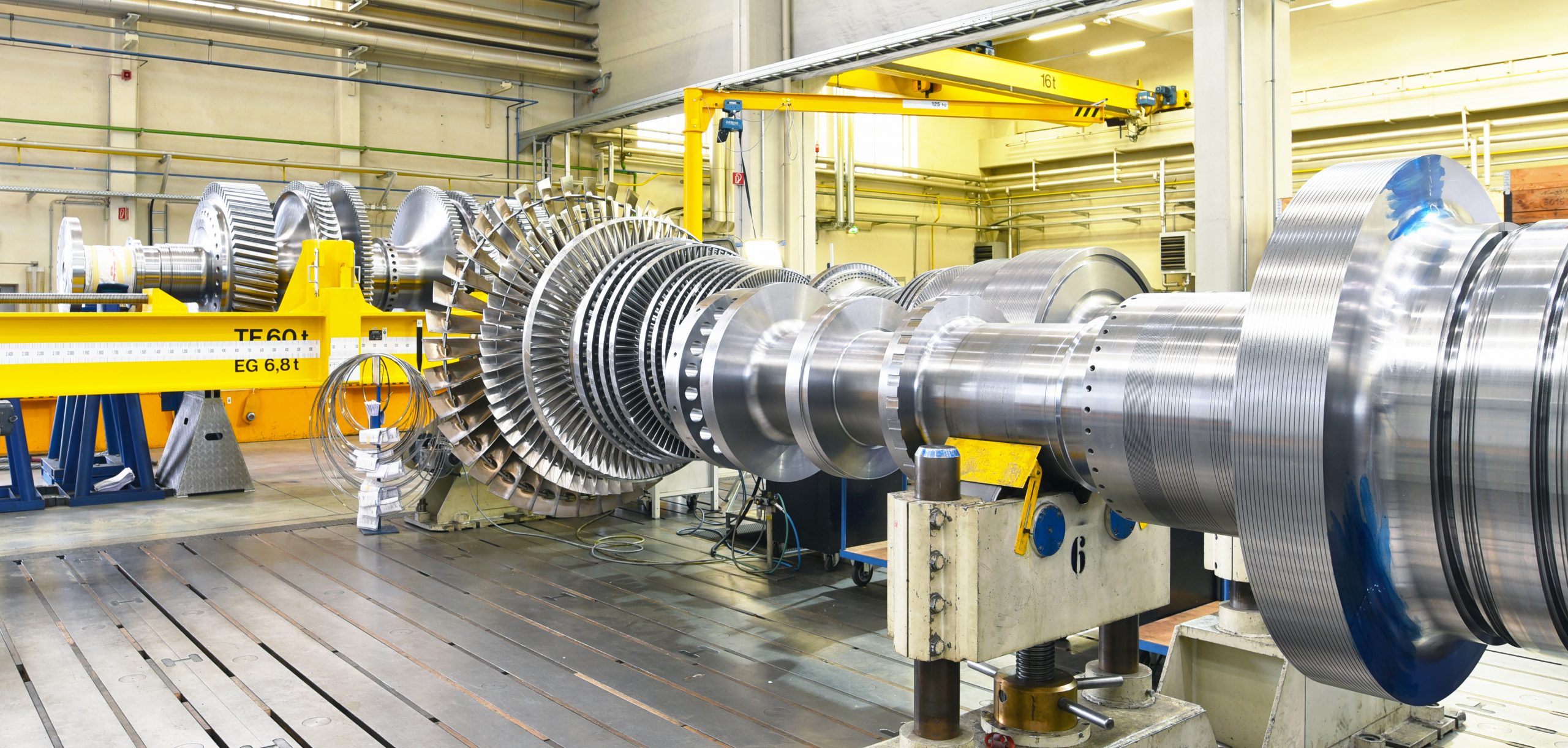

Several wind turbines across the US and Europe have experienced malfunctions ranging from component failures to full collapses, resulting in added costs for leading Western turbine makers, GE, Vestas Wind Systems, and Siemens Energy’s Siemens Gamesa unit. Industry veterans believe these events are becoming more frequent and could lead to higher insurance policies, undermining efforts to reduce dependence on fossil fuels and address climate change. The speed of production to create bigger turbines is being blamed for these malfunctions, and the three companies have acknowledged the challenges posed by rapid innovation and have focused on improving their manufacturing operations. However, higher material costs and supply chain problems are also posing a threat to the development of the US offshore wind industry. The absence of publicly available industry-wide data on turbine failures makes it difficult to get a clear picture of changes in performance over time, but Vestas and GE have confirmed elevated rates of machines unable to produce power, and Siemens Energy revised its 2023 earnings outlook downward, citing flaws in its installed turbines.

However, the recent increase in wind turbine malfunctions could pose a challenge for the renewable energy industry. The rush to produce larger turbines has resulted in quality and reliability issues, which have added hundreds of millions of dollars in costs for the three largest Western turbine manufacturers, GE, Vestas Wind Systems, and Siemens Energy’s Siemens Gamesa unit. Insurance premiums could increase or new coverage limits could be imposed if the failure rate continues to climb, according to Fraser McLachlan, CEO of GCube Underwriting Ltd. The lack of publicly available industry-wide data on turbine failures makes it difficult to assess the overall performance of the turbines over time, but GE and Vestas have confirmed that the share of their machines in the field that are unable to produce power has increased.

To address these quality issues, the turbine makers are focusing on improving their manufacturing operations and slowing down the introduction of new designs. GE CEO Larry Culp stated that rapid innovation strains manufacturing and the supply chain and that it takes time to stabilize production and quality on new products. Siemens Gamesa is addressing the quality and reliability of its products, and Vestas has acknowledged that the supply chain was not ready to handle the pace of product introductions, which has contributed to project delays, cost increases, and quality challenges.

Despite these challenges, the global expansion of wind energy continues to grow. The installed wind generation capacity has surpassed 840 gigawatts in 2021, up from less than 100 gigawatts in 2007, thanks to larger turbines. However, soaring material costs and supply chain problems have recently impacted the balance sheets of leading manufacturers, potentially slowing investment and hindering the development of the US offshore wind industry. The quality issues faced by the turbine makers add to these challenges, making it crucial for the entire value chain of renewables to mature to create a sustainable and profitable wind industry.