The efficiency of any turbine or engine can be defined as its ability to convert the input energy into useful output energy which is expressed in the form of the following equation.

Efficiency (ɳ) = Output / Input

An ideal turbine with 100% efficiency is the one which converts all its input energy into output work without dissipating energy in the form of heat or any other form. But in the real world, it is not possible to build a turbine with 100% efficiency because of friction in the parts of turbines, heat loss, and other such losses. In the case of steam turbines following factors decides the overall efficiency f the turbine.

- Velocity of input steam (which in turn depends on the temperature and pressure of steam)

- Angle of guiding vanes

- Blade angle on the rotor

- Radius of rotor

The electrical generating efficiency of standard steam turbine power plants varies from a high of 37% HHV4 for large, electric utility plants designed for the highest practical annual capacity factor, to under 10% HHV for small, simple plants which make electricity as a byproduct of delivering steam to processes or district heating systems.

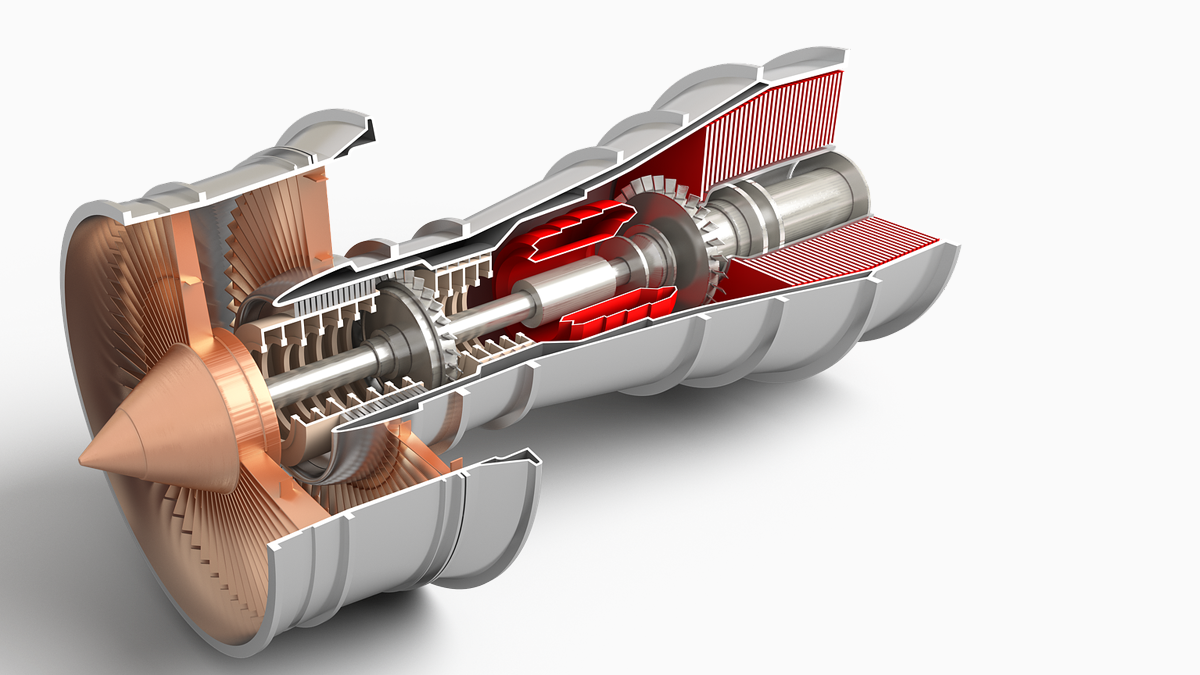

There are two types of steam turbines; impulse turbine and reaction turbine. Both types of steam turbines have different efficiency due to their different working principles but the efficiency of both types of steam turbines is expressed by the following equation.

Efficiency (ɳ) = Work Done / Input Kinetic Energy

Here input kinetic energy totally depends on the absolute velocity of the steam at the inlet of steam turbine but work done depends on lots of factors including drop in heat content of steam within the turbine, the angle of guide vanes especially at the inlet of turbines, blade angles, relative velocity of steam in the turbine, etc. It is fairly difficult to calculate work done by turbine because of all these factors and in some cases it is not possible to accurately calculate certain factors like velocity, temperature, or pressure of steam.

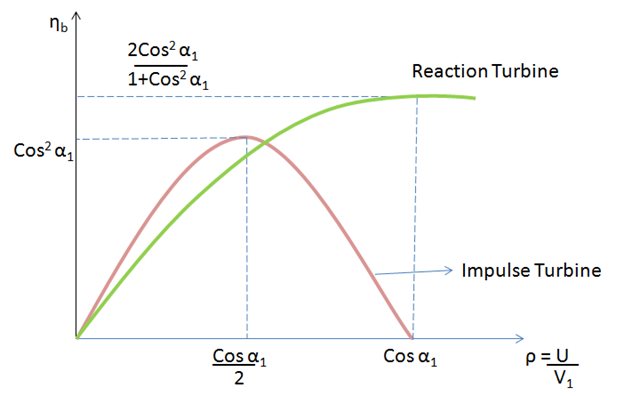

There are two ways of calculating steam efficiency. These methods referred as blade efficiency (ɳb) and stage efficiency (ɳs). Blade efficiency is calculated using the velocity of the steam while stage efficiency is calculated by measuring changes in the enthalpy of the steam. Enthalpy is referred to the heat content of the steam. In both cases the angle of guide vanes at the inlet plays an important role which is represented by α1. The cosine of this angle plays the central role in defining the efficiency of both impulse and reaction steam turbine.

The following figure 1 is showing the graph of blade efficiency for both types of steam turbines. This figure is indicating that reaction turbine is more efficient than impulse turbine.

Figure 1: Blade efficiency of impulse and reaction steam turbine

The maximum efficiency of impulse steam turbine is achieved at zero degrees angle of inlet blades because this angle keeps the friction at the minimum by reducing the surface area of the blade. It is also possible to link several turbines in series to utilize maximum energy from steam before sending it back to the condenser. In this type of arrangement stage efficiency calculation method works best. An important point to note here is that all this discussion did not include the energy loss in heating water and condensing steam. Commercial industries also calculate efficiencies of these operations to find out the overall efficiency of the entire setup.

Different Efficiencies of Steam Turbines

Isentropic Efficiency: This is the efficiency which compares the actual output with the ideal isentropic output to measure the effectiveness of extracted work.

CHP Electrical Efficiency: Combined Heat and Power (CHP) electrical efficiency measures the amount of boiler fuel converted into electrical energy or electricity. It can be calculated by following equation

CHP electrical efficiency = Net electricity generated/Total fuel into boiler

Total CHP Efficiency: This efficiency measures total output including electricity and steam energy by the boiler fuel. It is calculated by following formula.

Total CHP efficiency = (Net electricity generated + Net steam to process)/Total fuel into boiler

Effective Electrical Efficiency: This efficiency is calculated by the formula

(Steam turbine electric power output) / (Total fuel into boiler – (steam to process/boiler efficiency))

It is equivalent to 3,412 Btu/kWh/Net Heat Rate and

Net Heat Rate = (total fuel input to the boiler – the fuel that would required to generate the steam to process assuming the same boiler efficiency/steam turbine electric output (kW)

Heat or power ratio is also an important factor in this discussion and it can be calculated by the formula

Power/Heat Ratio = CHP electrical power output (Btu)/ useful heat output (Btu)

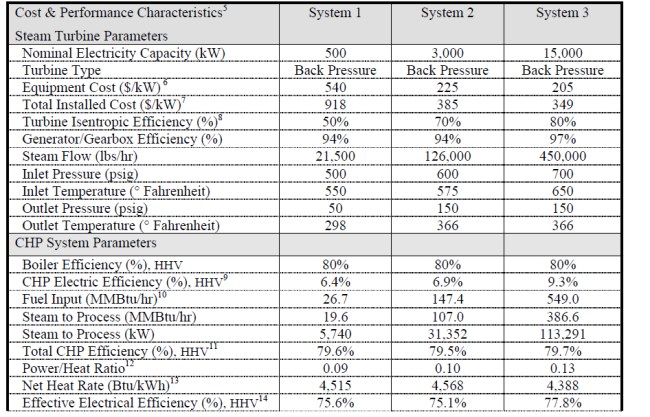

Following table 1 is showing the list of different performance characteristics f various commercial steam turbines. This table is for classic steam/boiler CHP system with the capacities of 500kW, 3MW, and 15MW.

Performance characteristics of typical steam/boiler CHP system